Solvent Extraction of Samples

Code: GE_404

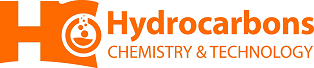

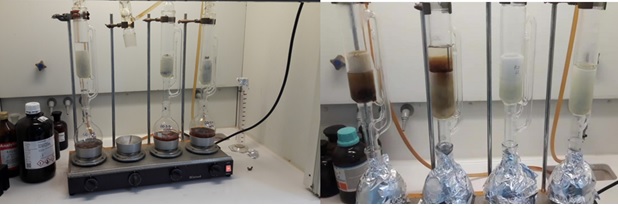

The sample is crushed in a mortar or in a mill and sieved in a 60mesh (250μm) sieve. After that it is placed for 12 hours in an oven at 60oC. The extraction of the samples is performed in a Soxhlet apparatus. 20-40g of the sample are weighed in a glass microfibre (GF/A) thimble and extracted for at least 24 hours (until the circulated solvent is clear) with 300ml of a solvent mixture of Dichloromethane and Methanol in a ratio of 9:1. Copper strip pre-treated with concentrated hydrochloric acid is placed in the solvent flask for the removal of free sulfur of the sample. The extract is condensed to 10ml in a rotary evaporator, filtered through a glass microfibre (GF/A) filter paper and collected in a pre-weighed glass vial. It follows solvent evaporation to dryness in nitrogen stream and determination of bitumen mass.